|

american

gas & chemical co. ltd.

D E T E C T I O N

T E C H N O L O G Y |

|

|

|

|

|

|

|

|

HOME |

Products |

Leak Detection |

Plant Maintenance |

Metal Integrity |

Glossary

|

Safety |

Gas Monitoring |

Personnel Protection |

Contact Us |

| |

ANSI Approved Standards for Colormetric Leak Testing

White Paper on

Colormetric Leak Testing

Leak Testing

Large Containers

Leak Testing Primer

|

|

| |

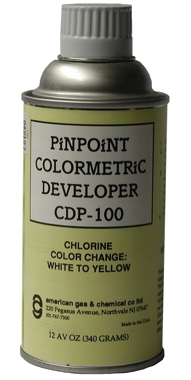

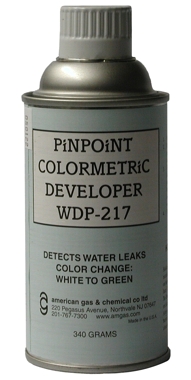

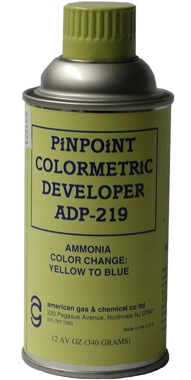

PiNPOiNT Colormetric

Leak Testing |

|

Colormetric detectors are rapid leak

detectors and inexpensive to use. They react

chemically with minute leaks causing a visible color change in the

developer.

They can be used to detect leaks up to 1x10-7 Std cm3/s

WHERE ARE

COLORMETRIC LEAK TESTERS USED?

Colormetric developers are used to leak test large single and

double walled tanks, pressure and vauum vessels, laminated, lined

or double-walled parts, complex piping systems, flexible

containers (such as aircraft fuel tanks), glass-to-metal seals in

hybrid packages and systems that inherently contain or will

contain the tracer (water, ammonia, chlorine or oil).

|

|

|

|

|

ANSI APPROVED STANDARDS FOR COLORMETRIC GAS DETECTION:

|

|

Tracer |

Name of Standard

|

|

|

Ammonia |

Developer Standard Test

Method for

Ammonia Colorimetric Leak Testing |

ASTM E1066

|

|

Water |

Developer Standard Test

Method for

Hydrostatic Leak Testing |

ASTM E1003

|

|

Available from the

American Society for Testing and Materials or from American

Gas & Chemical Co. |

|

|

|

|

Site Map

|

|

Copyright ©2025 American Gas & Chemical Co. Ltd., 220 Pegasus Avenue, Northvale, N.J. 07647-1977, U.S.A. 1-800-288-3647 or 1-201-767-7300 * fax: 201-767-1741 * purchase products from: https://detectorbuy.com |