|

Leak-Tec: Thin Film Bubble Testing Solutions

Thin film leak testing is the most common and

one of the most reliable methods of detecting and locating

leaks. Thin film bubble testing has many inherent

advantages:

• It is easy to

use and requires little operator training.

• It is inexpensive to use and not subject to break down

like complex instrumentation.

• It operates immediately and continues to give

indications.

• It can be extremely sensitive, finding leaks down to

1 x 10-6 (.000001) standard cc/second. The

equivalent of losing a pound of Freon every 2,700 years.

Sonic 3000: Ultrasonic Leak Detector

Leaks and other vibration sources produce a very broad band

of ultrasonic noise. This frequency is well above the sounds

which the human ear can hear. The Sonic 3000 has been set to

translate those frequencies into an audible output. It can

be used to solve a number of different maintenance and

quality problems.

Advantages

of the Sonic 3000:

• It can be used to detect a flow or leak of any gas or

liquid

• It can detect leaks rapidly and at distances up to 100

feet

• It requires little operator training

• It can locate internal as well as external leaks.

• It can accurately locate vacuum or pressure leaks

• It makes irregular, shaped or very large fittings easy

to test.

• It can detect internal arcing from faulty electrical

equipment.

• It works at low and high temperatures

• It can find intermittent leaks which many other

techniques cannot

• It can detect leaks in overhead lines, buried pipes and

in unpressurized areas.

• Its versatility means increased employee productivity

and less need for costly specialized equipment.

• It is portable, passive, non-destructive, non-intrusive

and requires no cleanup.

Immersit

By lowering the surface tension and increasing the wetting

ability of water, a leak in a pressurized immersed vessel

will generate a steady stream of tiny bubbles instead of an

occasional larger bubble as with untreated water. Small

leaks will produce bubble indications that are impossible

with normal water. The CIM series will not foam, will not

support bacteria growth and are formulated to prevent

corrosion. Although their use is recommended with deionized

water, they are chelated to be compatible with hard water.

Immersit additives are biodegradable.

Tracer Dyes

Tracer Dyes are mixed with water or oil to be tested for

leakage at its source. If the dye appears where there may

have been a leak, the leak is proven. Tracer dyes are used

in rivers, in toilets, in oil pipelines, and sewer systems.

Handheld Gas Tracers

for

Combustible &

Toxic Gases

Tracers are available depending on the gas to be found.

These tracers are:

• Sensitive - well below the OSHA limits and lower explosive

limits. In some gases the tracers will detect gases in

quantities as low as one part per million.

• They have been designed to be low maintenance and easy to

use.

• They are dependable, tough and rugged.

• They are priced to be AFFORDABLE

• They are designed to be easy to operate and learn.

Personnel Protection Indicators

Wearable and Disposable.

Protect yourself against dangerous gases with an instant

reading detector. An immediate color change is shown in the

presence of specific toxic gases.

Indicators are available for the following toxic gases:

• Carbon Monoxide

• Ammonia

• Nitrogen Dioxide

• Hydrazine

• Hydrogen Sulfide

• Chlorine

• Ozone

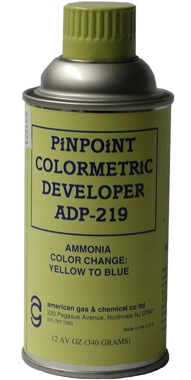

PiNPOiNT Colormetric Developers

Colormetric leak testing is useful for locating and

measuring gas leaks either as a quality control test for as

a field inspection procedure. It can be used to test

critical parts or containers that will hold toxic or

explosive gases or liquids or as a quick test for other

containers.

Colormetric developers are paints that are sprayed or

brushed onto the welds and joints of a container. A tracer

gas is introduced inside the container. Where a weld or

joint is leaking, the outside paint changes color to clearly

indicate where a leak is present. AGC offers several

formulas:

• ADP-219:

Ammonia Developer. To be used with ASNT Standard E1066,

Standard Test Method for Ammonia Testing.

• WDP-207:

Water Detecting Paint

• ODP-210:

Oil Detecting Paint

• CDP-100:

Chlorine Developer

SBG-200 Wall Mounted Gas Monitor

Monitor over 100 combustible and toxic gases including:

Ammonia, Butane, Carbon Monoxide, Ethylene Oxide, Gasoline,

Hydrogen, Methane, Propane, Natural Gas, Sulfur Dioxide,

Formaldehyde, Benzene, Acetone.

The SBG-200 is a solid state, completely self-contained

monitor capable of detecting gases. Several sensors are

available which allow it to be calibrated to alarm at gas

concentrations well below their lower explosive level or

OSHA ceiling. The monitor provides its own visual and

audible alarms as well as meter indication of gas

concentrations. A relay contact is provided to allow the

SBG-200 to connect with a central alarm system or turn on

emergency apparatus.

Flaw Finder Inspection Penetrants

Inspection Penetrants are a safe, sure, fast, easy sensitive

low cost way to find hidden defects in any non-porous solid.

All metals can be tested in this way. Penetrants highlight

flaws and leaks that are open to the surface and are too

small to see by normal visual inspection. Inspection

penetrants show the presence, location, nature and size of

defects. Penetrants are convenient. They can travel anywhere

in the field or be used where work space is limited.

Penetrants can be used on very large or complex items,

indoors or outdoors.

Penetrants are used worldwide by quality control, welding,

NDT and maintenance personnel. Almost all industries which

work with metal rely partially or exclusively on inspection

penetrants. Some of these industries are: engine

manufacturers and rebuilders, ship builders, train builders,

primary metal producers, metal fabricators, machine tool

manufacturers, etc.

TSI-301 Lubricant

TSI-301 is a specially formulated lubricant which sinks into

the pores of metal. Very little is required to take

advantage of its excellent lubricating properties. Even when

the surface of metal appears to be dry, the TSI-301 is

present, doing its job. It creates a thin film which tends

to uproot corrosion or contaminants. It bonds itself to the

surface of the metal through physical adsorption reducing

surface tension, practically eliminating friction and

reducing wear. It does not build up into gummy deposits.

Some advantages over other lubricants are:

• TSI-301

Cleans away rust and contamination better

• Low viscosity means

superior lubrication

efficiency

• Penetrates

faster

• Does not attract dust, dirt or lint

• Displaces water

better

• Increased wear

protection

• Wider temperature range (-60°F to +450°F)

• Reduced residue

• Less flash and fire hazard. It has

no flash point.

It is safe to use near fires and hot metals.

• Withstands extreme pressure

• Does not conduct electricity (anti-static)

• Prevents seizure

• Will not stain

Fluoro-Finder III Shot Peen Tracer

Shot Peening improves metal and weldment resistance

to fatigue, stress corrosion cracking and galling. To

provide this benefit, it is important that shot peen

coverage be uniform and complete. A liquid tracer

(Fluoro-Finder III) provides a coating which is removed at a

rate proportional to peening coverage, providing visual

feedback on the uniformity and completeness of peening

coverage. Fluoro-Finder III, has a pigment which fluoresces

under ultraviolet light making the determination of the

degree or percentage of coverage quick, easy and foolproof.

Use of this tracer eliminates the need for 200-percent

coverage in order to be assured of complete peening.

Stataway Anti-Static Topical Sprays

Two different formulations have been created to dissipate

unwanted static charges:

Stataway 1 is a

multipurpose antistatic spray. It is an easy, long-lasting

and inexpensive topical antistatic spray used for

dissipating, removing and preventing static charges. It

protects equipment by preventing dust attraction, and

removes static charges from garments and upholstery. It is

safe to use in manufacturing facilities for static control.

Stataway 2 is an easy,

long lasting and inexpensive topical antistatic spray used

for removing and preventing static charges on polyethylene

gas piping.

Water Detection & Hydrostatic Testing

We have many different water detectors each with a

technology designed to solve your problem. We have a

PiNPOiNT paint (WDP-218) that will change color when water

is present. We have a PiNPOiNT aerosol (WDP-217) which will

change color when water is present. We have a Tel-Tox WRAP,

which when wrapped around a pipe or a joint will change

color to alert you to the presence of water. We have a

number of EZ-Trace Tracer Dyes which when added to water

will give a fluorescent or color indication when a water

leak is occuring. We have self-developing Leak Tracers

for piping systems (FA-1A and GA-1A). These contain

corrosion inhibitors, chelating agents, mold inhibitors and

water soluable powders which will show the exact point

extent of leakage long after the water evaporates. See

our hydrostatic

page for more information and for links to buy these

products. |